- Policies and Basic Concepts

- Fields of Products That Reduce Environmental Impact

- Example: Wood-burning Biomass Power Plant

- Example: Materials Recycling Business

Policies and Basic Concepts

The Inabata Group believes that climate change and other global environmental issues pose risks to business continuity while presenting new opportunities for growth at the same time. We have highlighted “contributing to a decarbonized and circular society” and “sustainable use of natural capital” as part of our materiality issues, expressing commitment to resolving environmental issues through our business. As stated in the medium-term business plan NC2023, we are working to expand the lineup of products that reduce environmental load in all segments.

Fields of Products That Reduce Environmental Impact

In light of recent issues involving the global environment, we have reviewed the fields of products that reduce environmental impact. As indicated in the table below, changes have been made mainly to the clean technology area. We have used this framework for calculations and reporting since the FY2021 reports.

| Field | Main items | FY2021 net sales (millions of yen) |

|---|---|---|

| Energy & Power | Renewable energy and batteries | 13,463 |

| Resources & Environment | Sustainable materials, recycling and water | 4,201 |

| Materials & Chemicals | Low-carbon materials and environmental pollutant reduction | 735 |

| Agriculture & Food | Food waste reduction and soil improvement | 0 |

| Transportation & Logistics | EV charging and green logistics | 0 |

| Environmental certification | Forestry certifications (FSC and PEFC) and marine product certifications (MSC and ASC) | 328 |

| Total | 18,727 |

- Notes:

- 1. Coverage: Inabata Group (consolidated)

- 2. There are no results for Agriculture & Food or Transportation & Logistics in FY2021.

- 3. Totals are simple sums.

- 4. FY2021 net sales have been recalculated to match a 2023 review and partial reclassification of products within each field.

Although there are variations in figures for each product and field reported in 2022, totals remain unchanged.

Sales of the main products in the clean technology area are as follows.

(millions of yen)

| Energy & Power | Biomass power generation | 1,614 |

| Hydrogen | 223 | |

| Solar power generation | 8,087 | |

| Wind-power generation | 156 | |

| Lithium-ion battery | 3,383 | |

| Resources & Environment | biomass or recycled plastics, and biodegradable plastic materials | 1,510 |

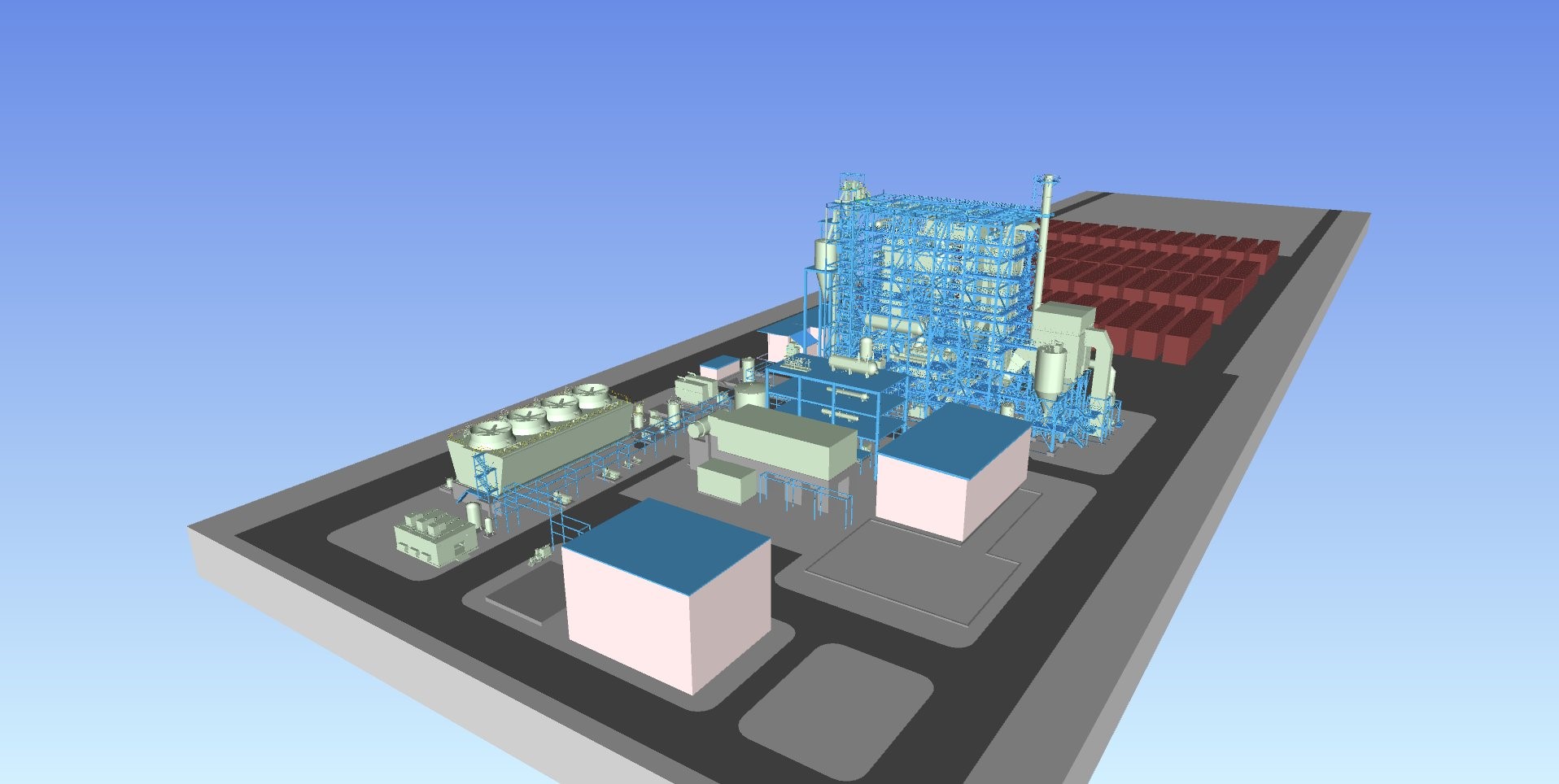

Example: Wood-burning Biomass Power Plant

Together with Chubu Electric Power Co., Inc., Taihei Dengyo Kaisha Ltd., Tokyo Sangyo Co., Ltd., Solariant Capital Co., Ltd. (“Solariant”), and Hitachi Zosen Corporation, Inabata & Co., Ltd. concluded an anonymous association agreement with Fukuyama Biomass Power Generation LLC (“the Project Company”), which was established by Solariant, and the Project Company concluded a loan agreement through project financing.

The Project Company will construct and operate the wood-burning “Fukuyama Biomass Power Plant” with power output of 52,700 kW in Fukuyama City, Hiroshima Prefecture, and aims to commence operation in May 2025. Estimated annual power output is approximately 380 million kWh (equivalent to electricity usage by about 120,000 ordinary households).

In this power generation project, Inabata will be entrusted with the management of wood chips (unused thinned wood from Hiroshima Prefecture, etc.) which is the fuel of the Project Company.

Conceptual image of completed power plant

Example: Materials Recycling Business

Inabata operates a materials recycling business that recycles waste plastic and used plastic generated in the manufacturing process at plastic processing plants. The business started out as a proposal to make efficient use of resources when a client company, a plastic processing manufacturer, was finding it difficult to dispose of waste plastic.

The waste plastic is collected mainly from plastic processing plants and distribution warehouses. It is then sorted, crushed, dissolved, and processed into recycled plastic pellets at partner recycling companies. Leveraging our long experience in the plastics business, we are involved in every stage from collecting to processing and selling waste plastic, and thus capable of consistently supplying high-quality recycled plastic material. The finished recycled plastic material is reused by plastic processing manufacturers. It is also processed by Group manufacturing and processing companies in Japan and abroad where it is turned into new plastic products. At present, we are expanding the lineup to familiar, everyday items such as reusable shopping bags, trash bags, and household containers.

Our materials recycling business deals in recycled plastic material that differs from the conventional recycled plastic materials handled by other companies. Since conventional recycled plastic is intended for mass production, the type, quality, and supply of plastic vary. However, we reduce production loss and variations in the quality of the re-pelletized plastic by carefully screening and managing the collected waste plastic. Moreover, we are able to achieve high quality and stable supplies by running physical property tests and dissolution tests on the re-pelletized plastic we produce.

By creating a new market where recycled plastic becomes added value, we aim to create a product that is sought after by brand owners with high environmental awareness.